Steel Grating

At NK Synergy, we provide a wide range of high-quality steel grating products designed to meet the rigorous demands of various industries. From construction and manufacturing to oil and gas, our steel gratings are trusted for their strength, durability, and versatility. Learn more about the benefits, product range, grating types, and field applications below.

Benefits of Steel Grating

Strength and Durability

Our steel grating is manufactured using high-quality materials, ensuring long-term structural integrity even under heavy loads. Ideal for floors subject to wheel and foot traffic.

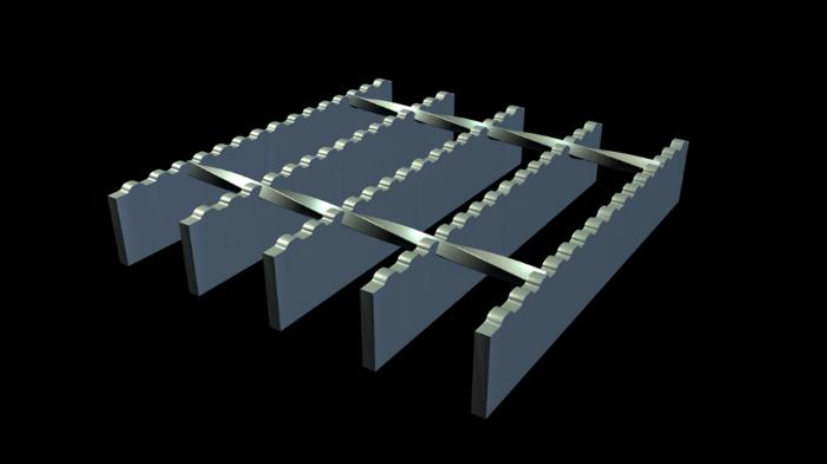

Non-Slip Safety

Serrated grating offers enhanced slip resistance, making it perfect for wet and oily environments, improving worker safety in high-risk areas such as offshore platforms and refineries.

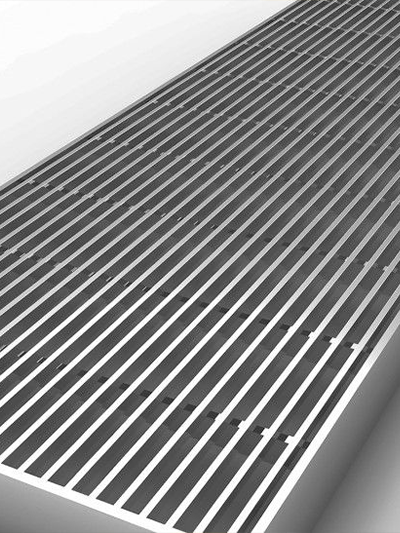

Ventilation and Light

The open design of our grating allows for excellent air and light flow, which makes it suitable for areas requiring proper ventilation like walkways and industrial floors.

Corrosion Resistance

With options like hot-dip galvanized or stainless-steel finishes, our grating provides superior protection against corrosion in outdoor or chemical-prone environments

Cost-Effectiveness

Steel grating is lightweight yet strong, offering an economical flooring solution that is easy to install and maintain, reducing project costs.

Product Range

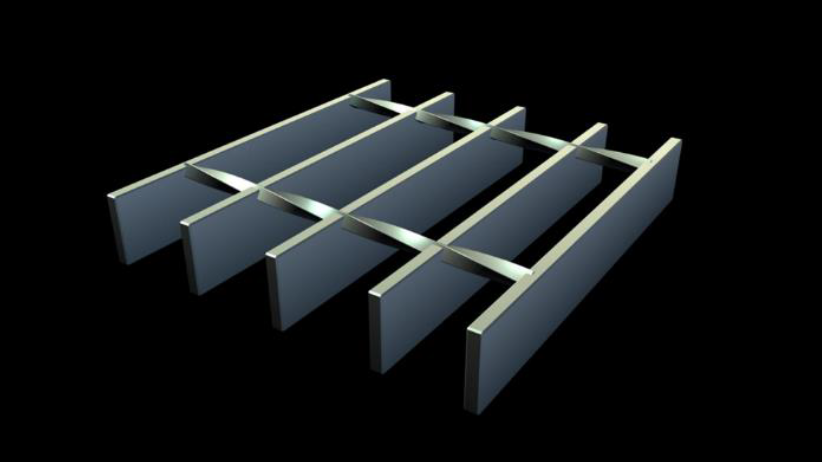

Mild Steel Grating

Available in various sizes and designs for general industrial use. Custom fabrication is available to meet specific project requirements.

Stainless Steel Grating

Best suited for harsh environments requiring high corrosion resistance, such as chemical plants, food processing facilities, and outdoor installations.

Galvanized Grating

Offers durable protection against rust and corrosion, making it ideal for outdoor applications.

Grating Types

Available in flat and I-bar designs, suitable for platforms, walkways, and other general uses.

Designed with notched load bars for enhanced slip resistance, widely used in oily, wet, or hazardous conditions.

Engineered to handle extreme loads, ideal for industrial flooring and bridge decking.

Field Applications

Industrial Flooring

Provides strong, non-slip surfaces for warehouses, factories, and refineries.

Drain Covers

Used in heavy-duty applications to prevent clogging while allowing water drainage.

Walkways and Platforms

Ensures safe and durable support in construction sites, marine decks, and high-traffic industrial areas.

Stair Treads

Serrated gratings enhance grip, reducing slips and falls in staircases.

Customization Options

We offer tailored solutions to meet your specific project needs, including custom sizes, shapes, finishes, and load capacities. All our products are manufactured to international standards like BS 4592 -1 (British Standard) and ANSI / NAAMM MBG531-00 (American National Standard). We use raw materials in accordance with BS EN 10025 Grade S275 JR or ASTM A 36 (from ASTM A 1011M). Hot Dip Galvanizing as per standards BE EN ISO 1461:2009 or ASTM A123.

| Component | Standard Sizes |

| Load Bar Height | 20mm, 25mm, 30mm, 32mm, 35mm, 38mm, 40mm, 45mm, 50mm, 55mm, 60mm |

| Load Bar Thickness | 3mm, 4mm, 4.5mm, 5mm, 6mm, 8mm, 10mm |

| Cross Bar Size | 6mm, 8mm, 10mm (Twisted Square/Round) |

| Grating Panel Width | Up to 1 meter (standard) |

| Grating Panel Length | Up to 6 meters (standard) |

| Pitch/Mesh Spacing | 30mm x 100mm, 40mm x 100mm, 30mm x 50mm, 40mm x 50mm |

Table can be scroll

Custom sizes and specifications are available depending on the project’s requirements, such as heavier loads, specialized finishes, or specific installation environments.