FRP Grating & Structure

Our Product Range

At NK Synergy Sdn Bhd, we specialize in providing FRP (Fiberglass Reinforced Plastic) and GRP (Glass Reinforced Plastic) solutions known for their strength, durability, and corrosion resistance. Our products are designed to meet the highest industry standards and are suitable for various industrial applications, including corrosive and high-temperature environments. Our product offerings include:

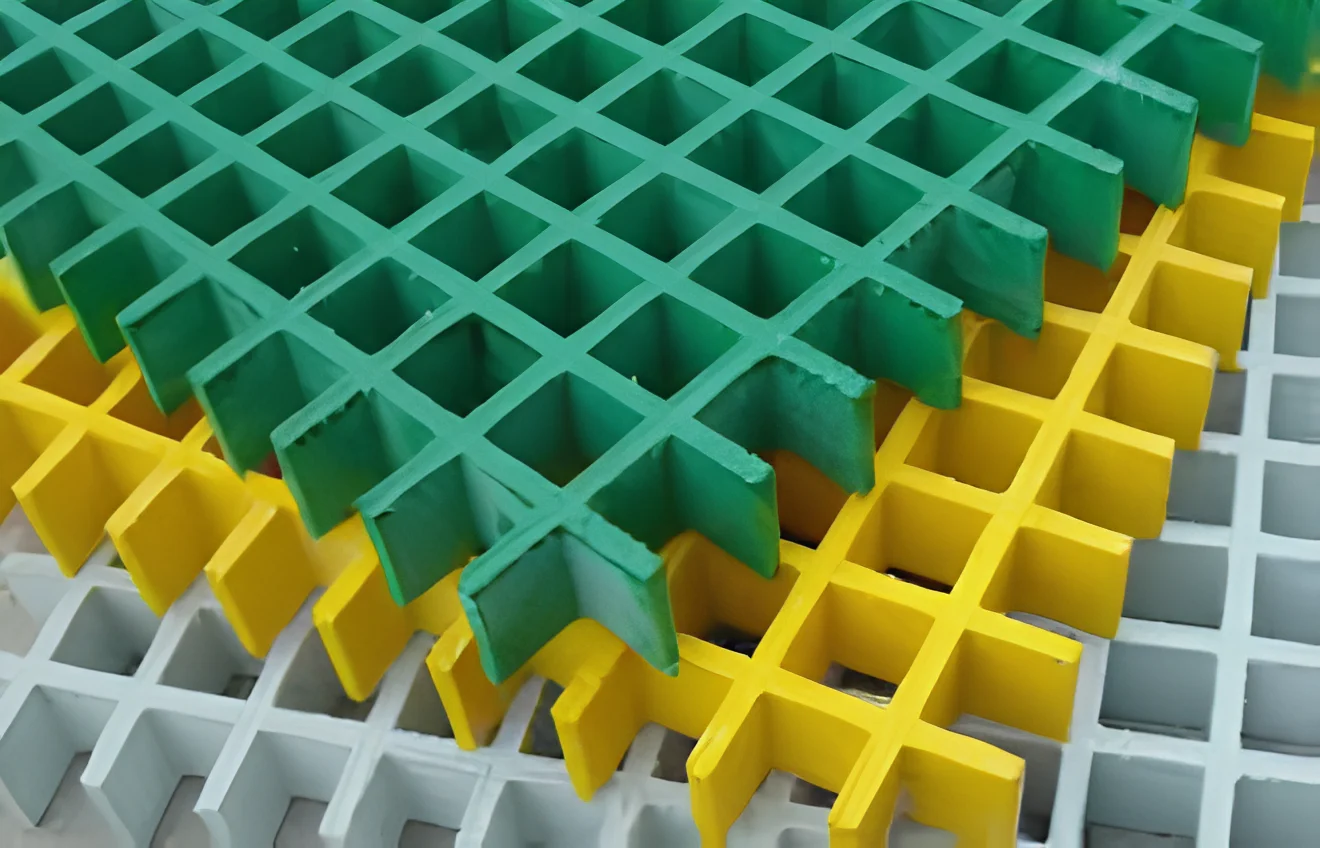

FRP/GRP Gratings (Molded and Pultruded)

FRP Handrails and Ladders

FRP Stair Treads

FRP Platforms and Structures

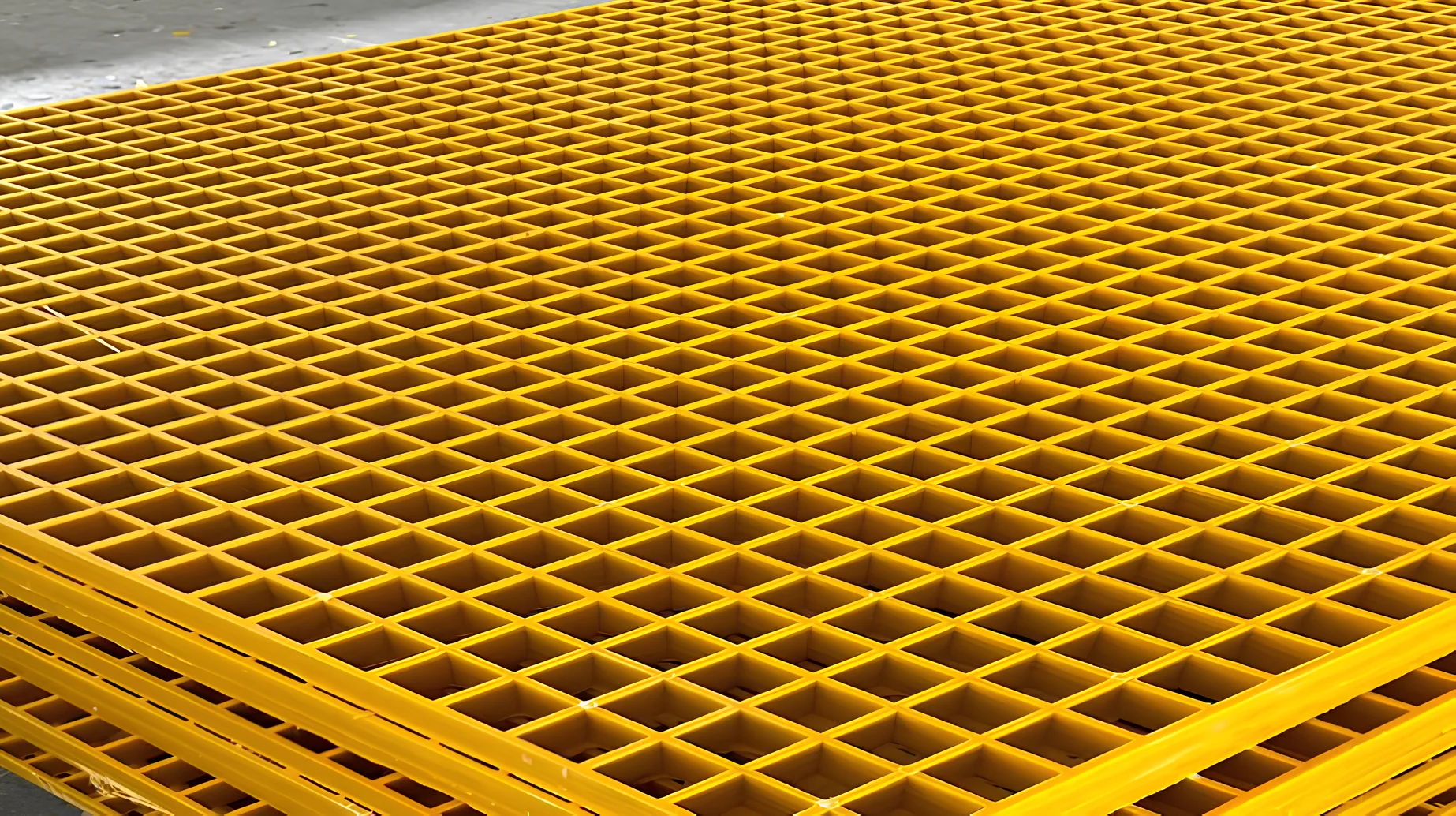

FRP/GRP Gratings

FRP/GRP Gratings are manufactured using high-strength fiberglass roving and resin systems (isophthalic polyester, vinyl ester, or phenolic resin), offering exceptional resistance to corrosion, fire, and impact. These gratings are available in both molded and pultruded forms, catering to different load-bearing and structural requirements.

Types of FRP Gratings

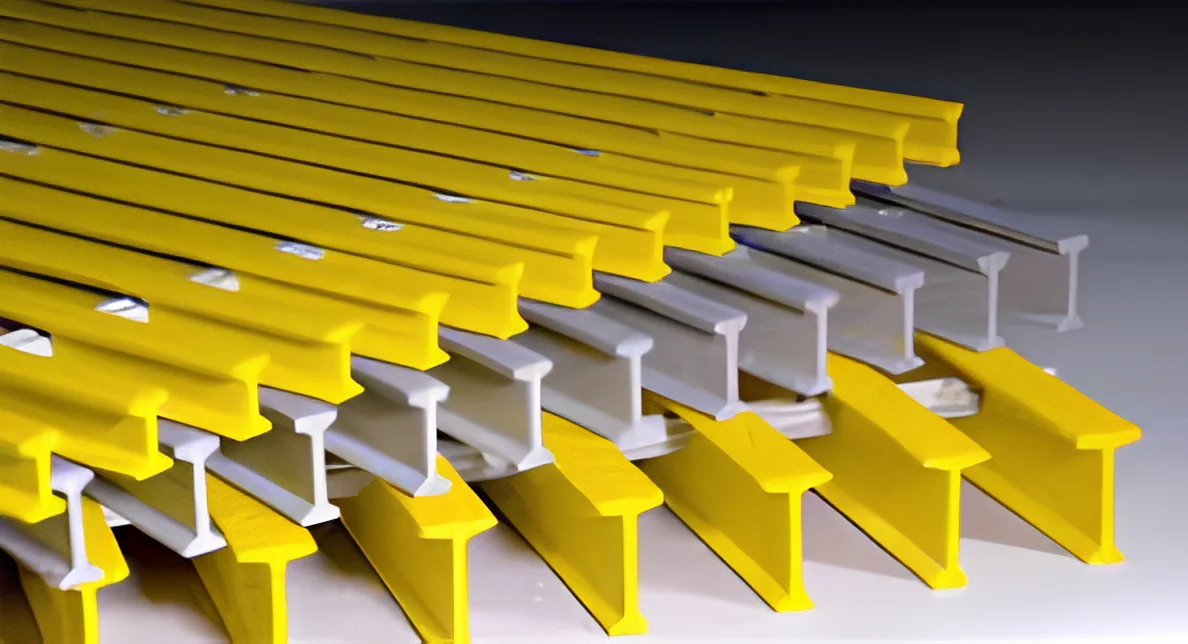

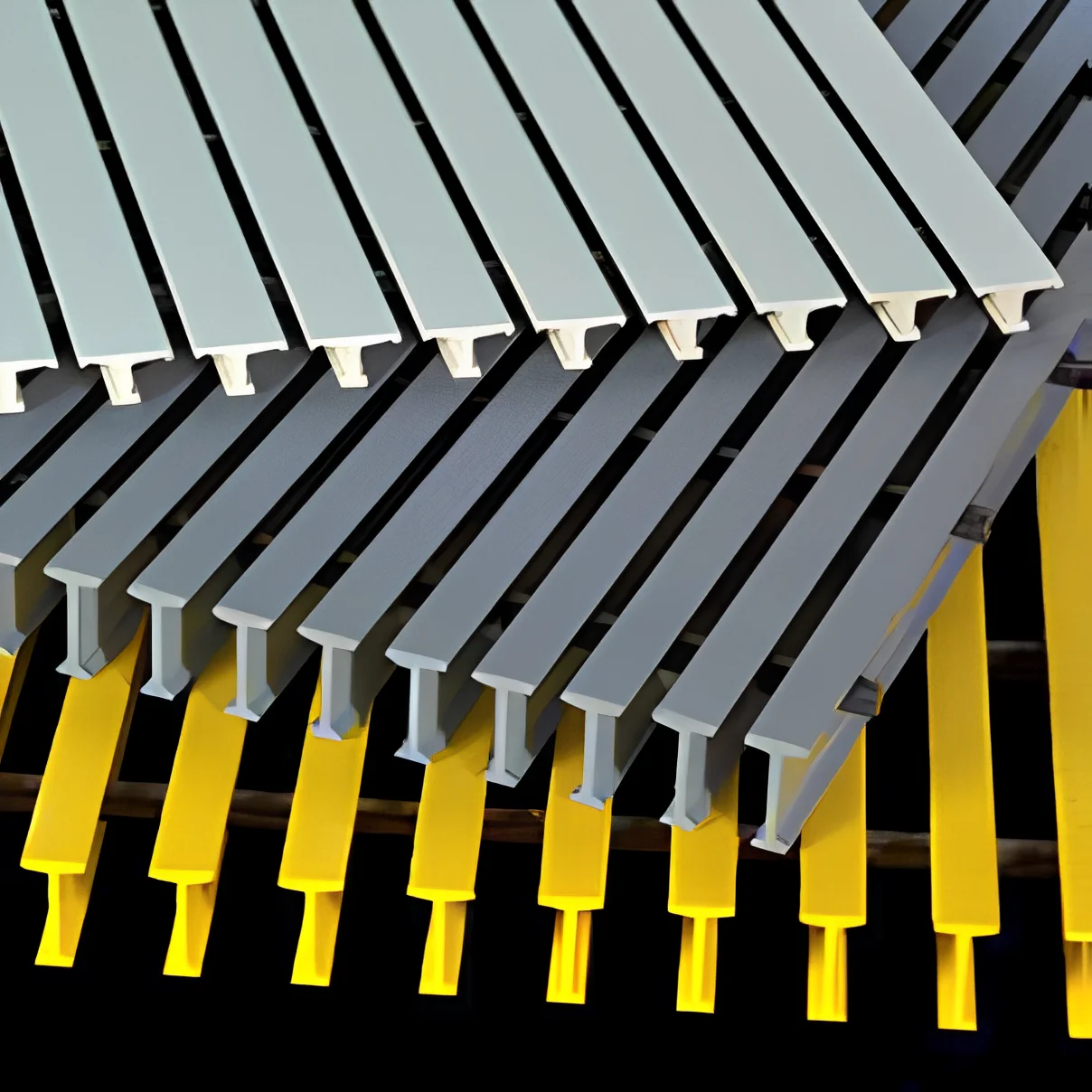

Composed of continuous fiberglass strands pultruded through resin to form a unidirectional load-bearing structure.

Designed for applications needing high strength and large spans.

Best suited for environments with greater load-bearing demands but lower impact requirements.

Technical Specifications for FRP Gratings

The table below provides a detailed comparison of various FRP grating types and their specific properties:

| Property | Molded Grating | Pultruded Grating | Phenolic Grating | Vinyl Ester Grating |

| Material Composition | Fiberglass + Polyester Resin | Fiberglass + Vinyl Ester Resin | Fiberglass + Phenolic Resin | Fiberglass + Vinyl Ester Resin |

| Corrosion Resistance | Excellent | Excellent | Superior (Chemical-resistant) | Superior (Chemical-resistant) |

| Fire Retardancy | Class 1 ASTM E-84 | Class 1 ASTM E-84 | Class 1 ASTM E-84, Low Smoke | Class 1 ASTM E-84 |

| Maximum Operating Temperature | 65°C | 82°C | 150°C | |

| Tensile Strength | 120 MPa | 206 MPa | 200 MPa | 206 MPa |

| Flexural Strength | 150 MPa | 241 MPa | 241 MPa | 241 MPa |

| Impact Resistance | High | Medium | High | High |

| Weight | Light (1/4 of steel) | High | Light | Light |

| Slip Resistance | High (Gritted or Concave Surface) | High (Gritted Surface) | High (Gritted or Meniscus) | High (Gritted) |

| UV Protection | Yes | Yes | Yes | Yes |

Table can be scroll

Why Choose FRP Gratings?

Corrosion Resistance

FRP gratings are chemically inert and can withstand corrosive environments such as chemical plants, wastewater treatment facilities, and marine settings.

Strength-to-Weight Ratio

Despite being lightweight (1/4 the weight of steel), FRP gratings offer strength comparable to steel, making them easier to handle and install without compromising structural integrity.

High Temperature and Fire Retardant

With a Class 1 ASTM E-84 fire rating, FRP gratings meet stringent fire safety standards. Phenolic resin gratings, in particular, offer superior fire resistance and low smoke emission, making them ideal for offshore and hazardous environments.

Slip Resistance

Available with both concave and gritted surface finishes, our gratings minimize the risk of slips and falls in oily, wet, or high-traffic areas.

Impact Resistance

FRP gratings have high impact tolerance, allowing them to withstand heavy industrial use without permanent deformation.

Applications of FRP/GRP Products

Our FRP/GRP Gratings and Handrails are extensively used across a wide range of industries, including but not limited to:

Oil & Gas Platforms

Excellent resistance to saltwater corrosion and extreme weather conditions.

Chemical Processing Facilities

Ideal for environments with exposure to acids, alkalis, and solvents.

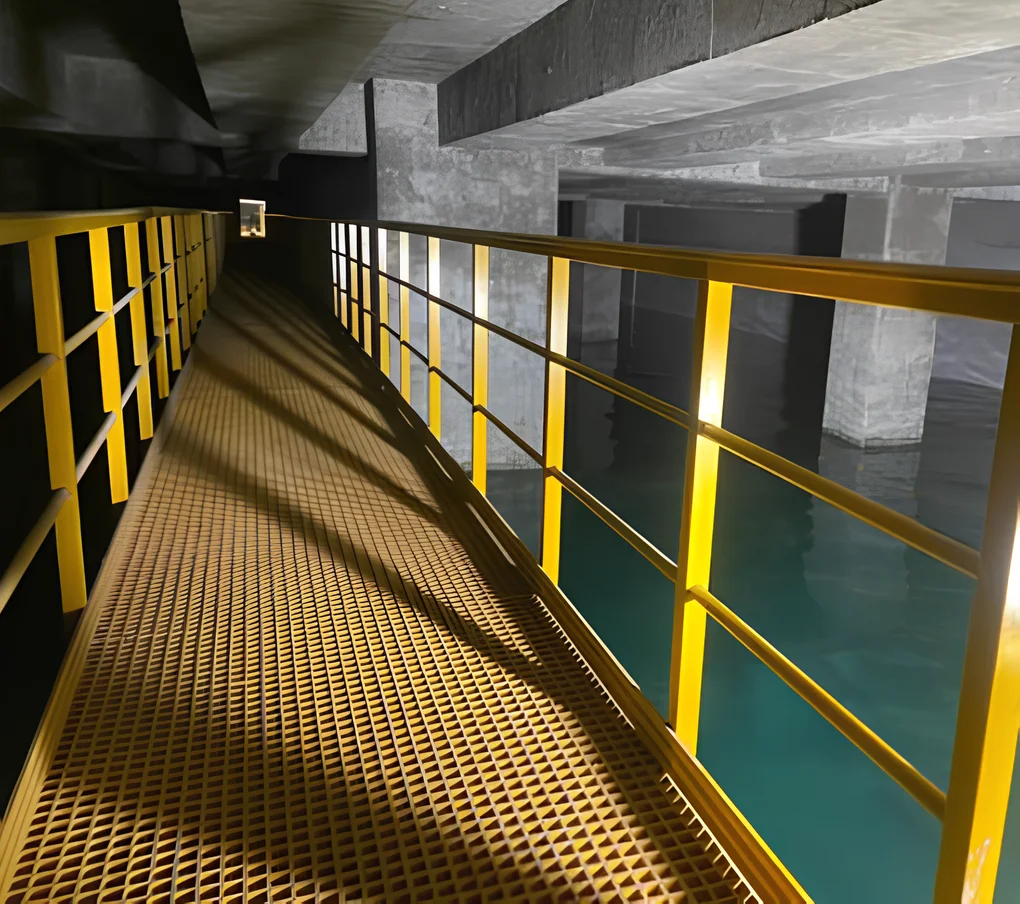

Marine and Offshore Installations

Lightweight and resistant to marine corrosion.

Wastewater Treatment Plants

Highly durable in wet, corrosive environments.

Mining

Long-lasting with high impact and chemical resistance.

Pharmaceutical Industries

Non-corrosive, hygienic, and easy to clean.

FRP/GRP Handrails

Our FRP Handrail Systems are designed to provide maximum safety and stability in industrial settings. The systems are easy to assemble, lightweight, and require minimal maintenance, making them ideal for harsh environments.

Technical Specifications for FRP Handrails

| Property | Value |

| Tensile Strength | 240 MPa |

| Flexural Strength | 320 MPa |

| Load Capacity | Up to 500 kg/m² |

| UV Resistance | Yes |

| Corrosion Resistance | Excellent in coastal and chemical environments |

| Fire Retardant | Class 1 ASTM E-84 |

| Impact Resistance | High |

| Modular Design | Yes (Easy to install and modify) |

Table can be scroll

Advantages of FRP/GRP Handrails

Corrosion and Chemical Resistance

Ideal for outdoor and chemical-heavy environments.

Low Maintenance

Resistant to rust and rot, eliminating the need for frequent maintenance.

High Strength and Safety

Offers high load-bearing capacity while remaining lightweight and easy to handle.

Non-Conductive

Safe for use in environments with electrical risks.

Product Benefits

Long Service Life

FRP products are resistant to corrosion, weathering, and UV damage, ensuring a long lifespan and reducing replacement costs.

Lightweight and Easy to Install

FRP products are lighter than metal alternatives, allowing for quicker and more efficient installation.

High Safety Standards

Designed to meet fire, slip, and impact safety regulations, ensuring a safe environment for workers.

Eco-Friendly:

FRP products are 100% recyclable and have a lower environmental impact compared to traditional materials like steel.

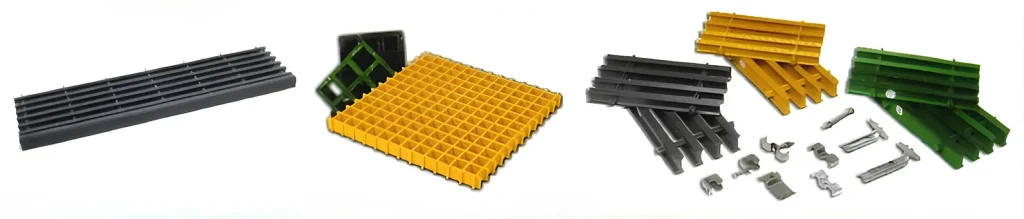

Full Range of FRP Products

Grating & Stair Tread

Cable Ladder & Cable Tray

Handrail & Caged Ladder System

Structural Support System